Hydrogen Brazing

Hydrogen brazing is a process of joining two or more metal components using a filler metal that melts at a temperature higher than 840C (1544F) but lower than the melting point of the base metal. The process is carried out in a hydrogen atmosphere to prevent oxidation of the metal surfaces during the brazing process. Hydrogen brazing is commonly used in the aerospace, automotive, and electronics industries for its ability to create strong, leak-tight joints that can withstand high temperatures and pressures.

One of the main advantages of hydrogen brazing is its ability to produce high-quality, clean joints. The hydrogen atmosphere helps to prevent oxidation, which can weaken the joint and compromise its integrity. Additionally, hydrogen brazing can be used to join dissimilar metals, such as copper and steel, which can be difficult to join using other methods. The process is also environmentally friendly since hydrogen is a clean-burning fuel and does not produce harmful emissions or waste products. Overall, hydrogen brazing is a reliable and efficient method of joining metal components, and it is a popular choice for industries that require strong and durable joints.

How We Can Help

We are experts in Hydrogen Brazing

- Experienced technicians trained in hydrogen brazing techniques

- Hydrogen brazing is a clean, efficient, and cost-effective method of joining metal parts

- Hydrogen brazing can be used in a variety of industries, including aerospace, automotive, and manufacturing

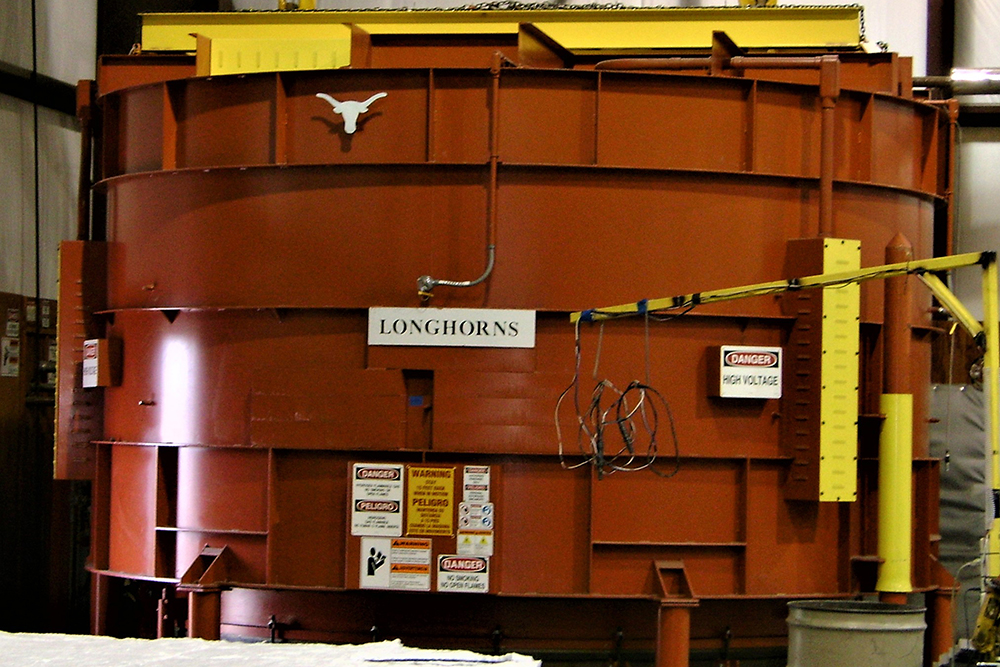

- Pal-Con uses high-quality equipment and materials to ensure optimal results

- Hydrogen brazing can help to improve product quality and reduce the need for additional finishing processes

- Pal-Con's hydrogen brazing services are customizable to meet each customer's unique needs

- Pal-Con provides comprehensive support and maintenance services to ensure long-term success

You Should Know

Pal-Con offers hydrogen brazing services to customers in a variety of industries, including aerospace, automotive, and manufacturing. Hydrogen brazing is a clean, efficient, and cost-effective method of joining metal parts. Pal-Con's experienced technicians are trained in hydrogen brazing techniques and use high-quality equipment and materials to ensure optimal results. Hydrogen brazing can help improve product quality and reduce the need for additional finishing processes, while also being customizable to meet each customer's unique needs. Pal-Con's comprehensive support and maintenance services ensure long-term success for customers utilizing hydrogen brazing in their operations. Overall, Pal-Con's hydrogen brazing services provide customers with a reliable and effective solution for joining metal parts in various industries.